There are many types of packaging prevalent these days, each and every packaging displaying efforts and creativity. But, if we look at it broadly, there are only two types of packaging.

One being the Flexible Packaging and the other being the Rigid Packaging. Both types of packaging serve their own purposes distinctly.

But you need to find out the right packaging design for your business, depending upon the type of commodity you are serving. This will benefit you in the best possible way. We need to know if a rigid box manufacturer is what you require or a flexible one, so let’s take a look at the article for the same.

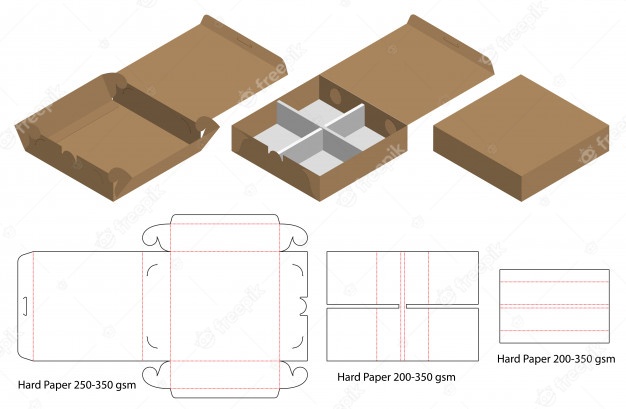

Rigid Packaging is a type of packaging which includes rigid designs. Rigid designs like those of cans, tins, cardboard boxes as is shown in the image, and containers of glass. Examples of such types of packaging would be bottles, soda cans, jars, etc.

Due to the above-mentioned features, if you are worried about the protection of the product that the packaging is set to carry, in that case, you should go for the Rigid Packaging type as it offers good protection which will keep your product safe.

Rigid Packaging Materials are way better at keeping the products safe and sound. They will ensure that the product is delivered safely to the customer’s place.

For Rigid Packaging, mostly the materials used for making the packages include:

It is important to note that plastic packaging dominates the global market in the field of rigid packaging. It’s because plastic doesn’t deteriorate and helps to keep the packaged materials in a good shape for a long time. Along with that, plastic is one of the cheapest options for rigid packaging.

If you are looking for a reputed and trusted custom rigid boxes wholesale provider, then you can always check out Hongyi, as they have a good collection of plastic, wooden, and cardboard packaging options.

Rigid Packages are made up of materials that can’t be bent and are fixed. Hence, Rigid packages provide good strength and support to the products.

The rigid box design is made up of hard materials like metals and plastics. The most popular applications of rigid packaging incorporate:

Below are the key advantages of rigid packaging:

Rigid packages are superior to flexible packages in terms of strength. They can carry the product more safely and securely than the flexible one.

Glass is an example of the good quality materials used in packaging. Luxury rigid box manufacturers should work to make the quality even better.

Below are the key drawbacks of rigid packaging:

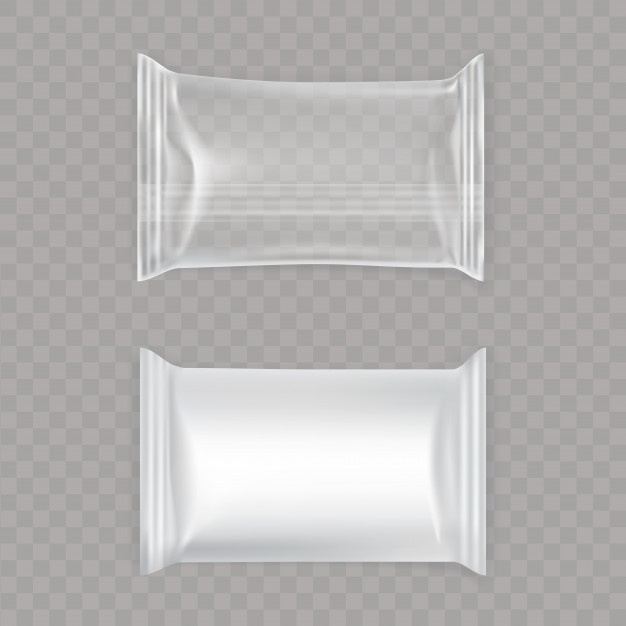

Flexible Packaging Definition– Flexible Packaging incorporates all kinds of malleable packaging. Examples of such types of packaging are stretch film, shrink film, flexible pouches, seal bands, clamshells, and blister or skin packs. Flexible Packaging has taken the packaging industry by storm and it is preferred more by people these days. Rigid packaging is losing its place to flexible packaging because of several reasons-

The below materials are used in the flexible packaging process:

As we have discussed earlier, rigid packaging is way heavier than flexible packaging. It is because of the material used in rigid packaging which is mostly metal, wood, cardboard, or plastic.

On the other hand, light material is used to make flexible packages. Material such as polypropylene, causes the packaging to be light weighed.

Rigid packaging protects its contents in a much better way than flexible packaging. However, rigid packaging is prone to deformation due to the external environment sometimes. In the case of flexible packaging, it does not deform or get dented easily.

Overall, flexible packaging is less likely to be affected due to the external environment and does not get affected by cosmetic abrasion either. Also, flexible packaging is preferred over rigid packaging these days.

As we stated earlier that flexible packaging has one advantage over rigid packaging that it can be modified and made aesthetic. Flexible packaging is open to customization whereas this is not the case with rigid packaging.

Rigid Packaging is really difficult to carry out and has less scope for customization. Designs can’t be printed on the packages just like that, they have to be printed separately and then attached to the package. Custom rigid boxes are hard to make.

When we have to choose between the two, rigid or flexible packaging, there is no right or wrong option. It depends on what feature you prefer in your packaging and what kind of materials you wish to use. Here are seven factors that you must consider before making a choice:

Factors that influence the choice between the two are:-

Does the product, which the packaging will carry, need any kind of protection? If the content is liquid in form, you should go for flexible packaging. However, if the content is of gaseous form in nature, prefer rigid packaging instead.

If you want to showcase the good quality of the package, you should go for rigid packaging undoubtedly. The quality of the rigid packages is strong in nature.

Flexible packaging can be customized and made aesthetic whereas rigid packaging adds a high-end appeal to the items being packaged.

Rigid packs are very easy to store whereas flexible packages can also be tossed into the air and nothing would be damaged. Rigid Packaging is done in such a way that it protects its contents and delivers it safely to the customer. Flexible Packaging can be bent in any form or shape.

If you have a low budget and wish to accommodate it only, you should then go for flexible packaging as it is less expensive than rigid packaging.

As for the costs for both the type of packaging, there you go:

If your product requires protection from extreme temperatures then rigid packaging is ideal for you. Due to the immense strength of the rigid package, no harm is likely to be inflicted upon the content inside the box.

If you wish to have a great impression through the packaging, you should go for flexible packaging as it will allow you to be creative and will help you to customize the packaging according to your own needs.

All the information we displayed in the article above will help you to make a good choice, it will enlighten you on the merits and demerits of both packaging systems. We hope that this helps you in making the right choice.

In the end, it all depends on your choice, if you wish to have an aesthetic box or a normal package. However, if you require rigid packaging, then you should contact a reliable rigid box manufacturer like Hongyid for all your needs.

Let your perfume brand be known the world over with unique packaging brought by your custom perfume box manufacturer Hongyi.